Oil Seals

The oil seals represent the most important type of dynamic sealing on rotating shafts. During the last years, we witnessed a great evolution in the technology, starting from their shape to the materials used nowadays.

In fact, modern and outstanding engine concepts require new and outstanding properties and solutions for dynamic seals, which continuously can withstand the high loads.

Following a short description of the oils seals Elwis Royal offers to the markets, respecting the highest possible quality and performance to meet the expectations of the most demanding customers.

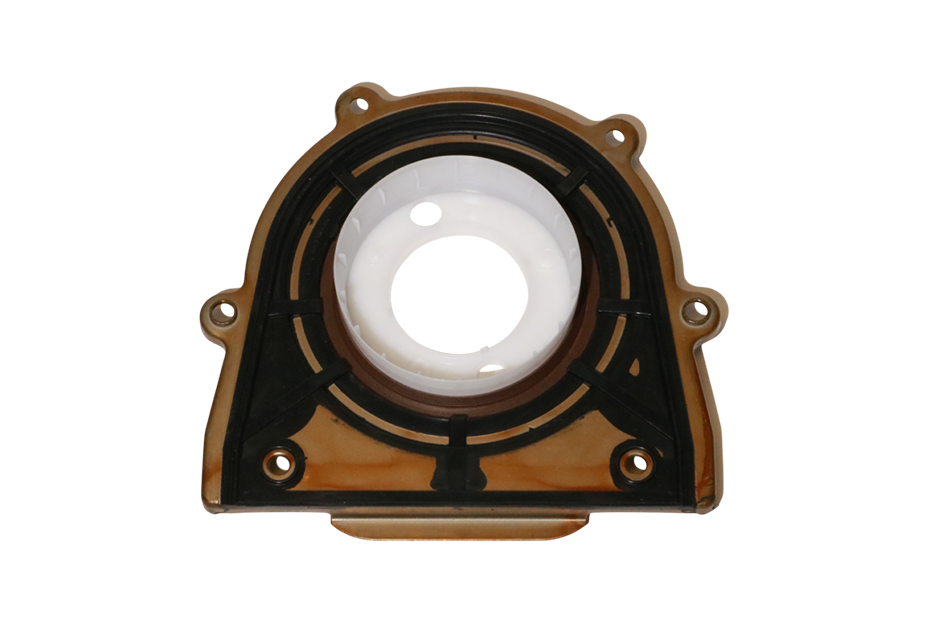

Conventional oil seals

Classical oil seals consist of a metal housing that carries the dynamic sealing lip and provides the static sealing function. These are usually manufactured of elastomer material, such as ACM, Silicone or FPM. Further, since they are in contact with the surface of the rotating shaft, the lip is pressed onto the shaft surface by means of a spring ring.

Heat and attrition are generated by the parts moving against each other. The sealing function can only be ensured if an intentional defined leakage of oil is able to exit for seal lubrication, preventing seal wear and possible failure, while a tight static seal between shaft and sealing lip must be assured when the shaft is stationary.

Elwis Royal meets all these technical requirements.

Elastomer material + PTFE – The perfect combination

This represents a new generation of oil seals.

Modern engine concepts, like higher engine speeds and oil temperatures, longer intervals between oil changes and lubricants with modern additives, require new solutions for dynamic seals. They have to withstand the high loads lastingly. PTFE technology is the answer, since it perfectly meets these demands.

The advantages are low friction and minimum power consumption, the possible use even in case of insufficient lubrication, operating range of -130º c to +200º c and much more: high chemical resistance and a low breakaway torque after standstill. Further, the PTFE, when heated, can” remember” its original form and return to it (phenomenon known as” plastic memory effect”).Therefore, this kind of seal do not need the old school metallic spring.

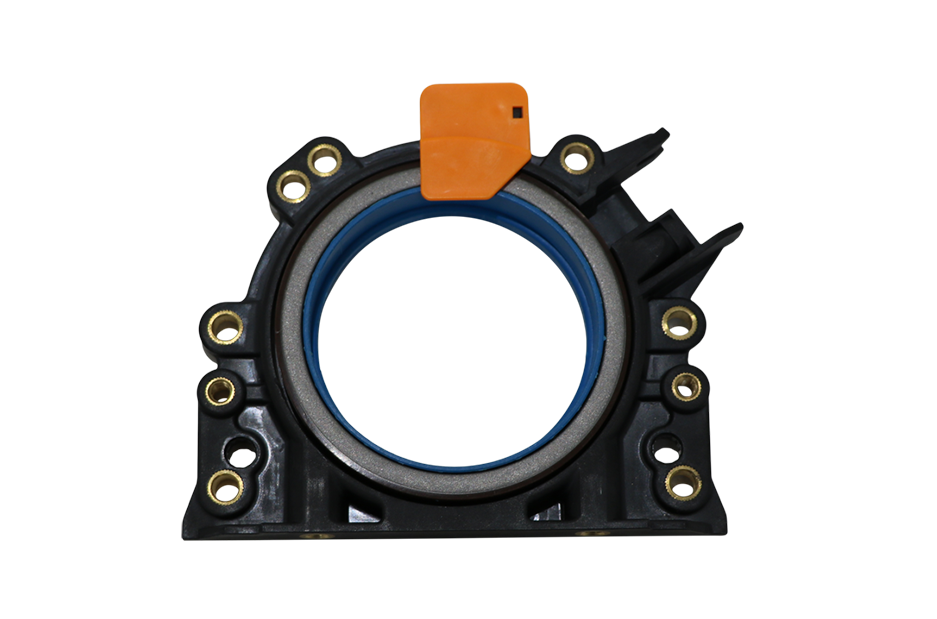

Integrated oil seals

The reasons for the birth of this new generation of seals is that integrated oil seals reduce the manufacturing time of series production engines. Therefore, significant time savings are achievable when replacing the radial crankshaft seals.

The interaction of the integrated seals with the shaft follows the dynamics of the PTFE seals. Often an additional dust seal (rubber lip or felt strip) provides an effective barrier against contaminating particles.

These new oil seals can also be equipped with a shaft rotation sensor.

To install them, both correctly and professionally, it is essential to use the right special tool for the replacement part. We recommend replacing this component with the aid of OE repair manuals with complete and extensive instructions.

Elwis Royal offers customers a wide range of integrated oil seal following the OE quality and using the best materials the market can offer.